Structured around 5 technical platforms, the MASMECA (Advanced Experimental Mechanics on Materials and Structures) technology platform links research centers with local socioeconomic and industrial organizations, promoting vigilance and transfer of technology to businesses.

MASMECA provides industrial firms with access to its experimental facilities and skills with the aim of:

- promoting transfer of technology and techniques;

- meeting businesses’ testing needs and contributing to innovation;

- developing partnerships between research centers and socioeconomic and industrial stakeholders;

- expanding the platform’s resources.

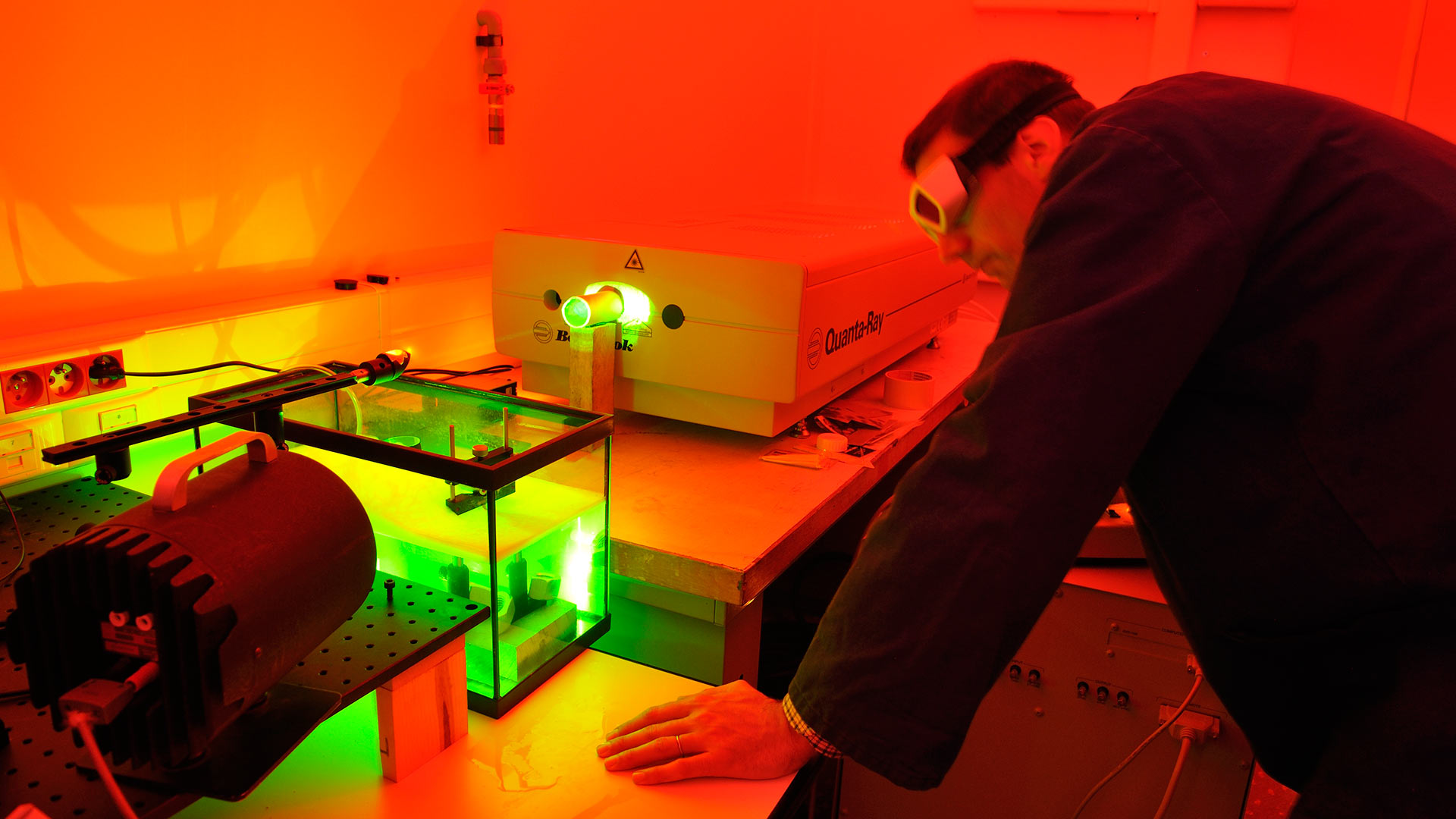

Equipment for high-speed loading tests

- Hopkinson Bars

- Taylor Gun

- Shock tube

- Shock machine with retractable tank for water impact testing

- Spectra-Physics Quanta-Ray Pro 350 pulsed laser

- IDIL Photonic Doppler Velocimeter (maximum speed 20km/s, 1550nm laser)

Loading samples and structures in controlled mechanical and environmental conditions

- 3 servo-hydraulic tension-compression testing machines

- 4 electro-mechanic testing machines

- 2 servo-hydraulic tension-compression/torsion testing machines, including a Tema Concept machine

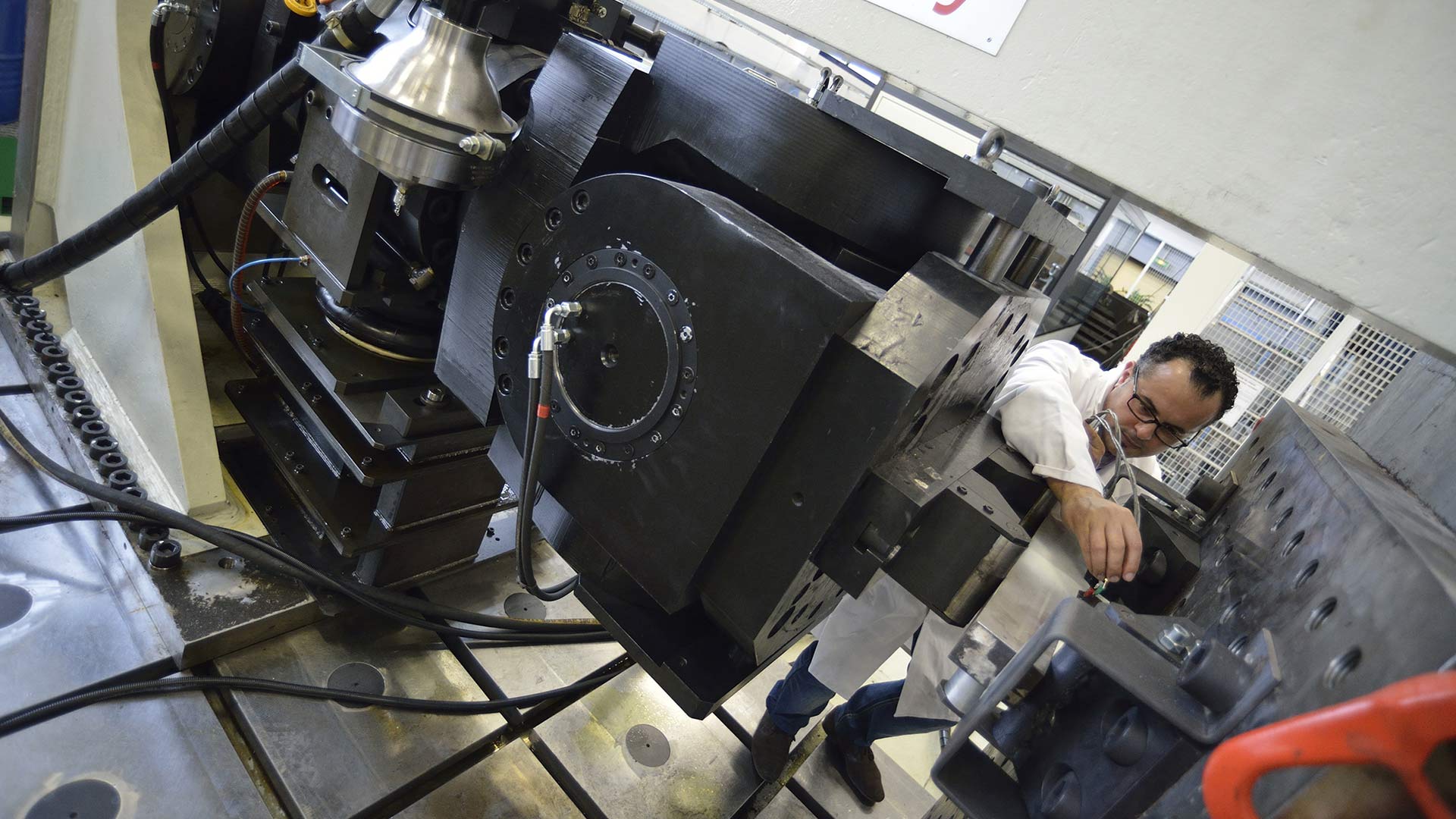

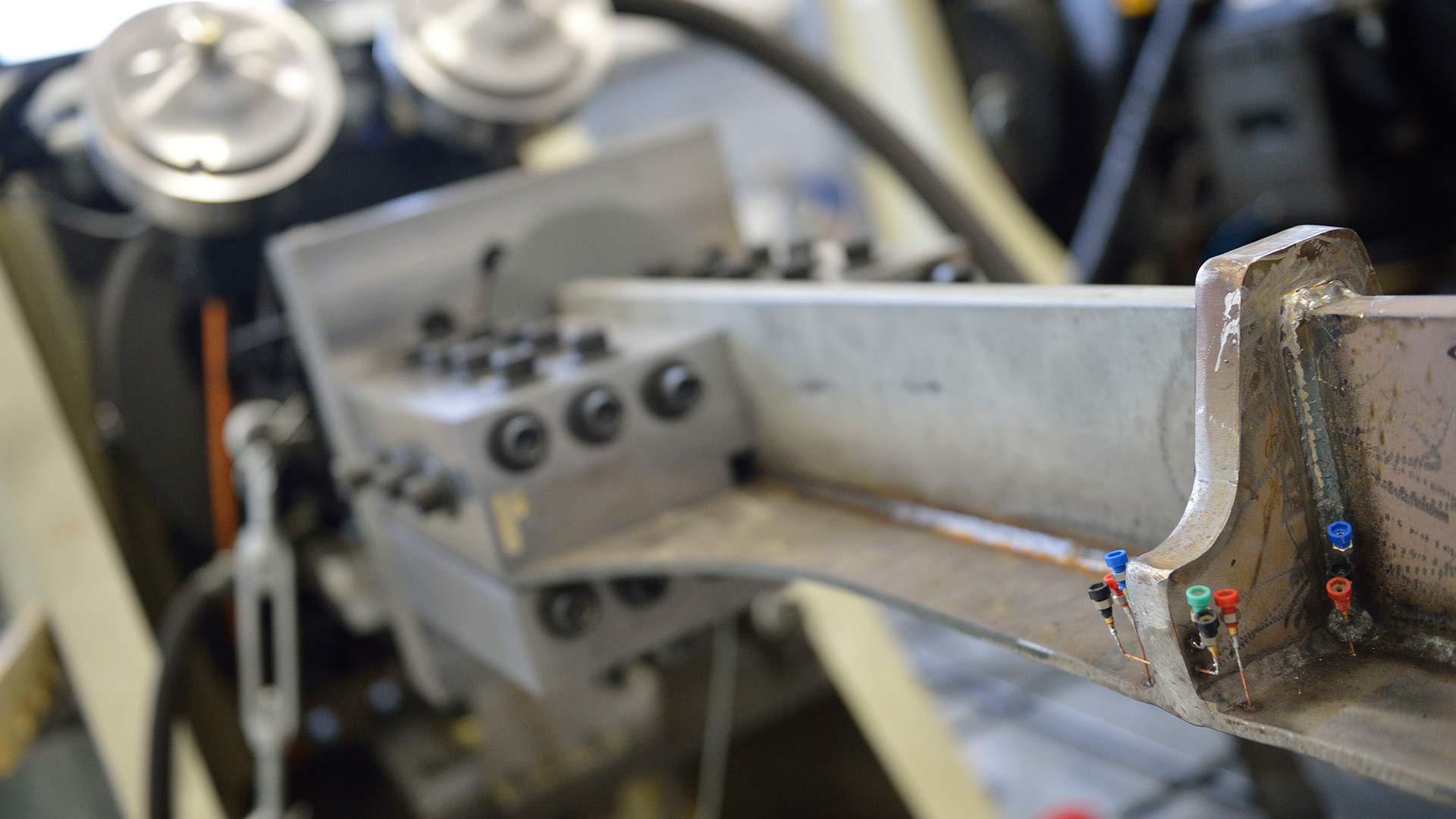

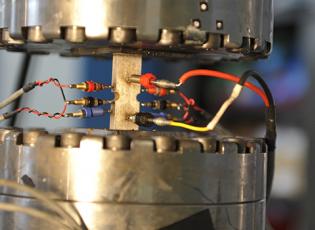

- Tri-axial servo-hydraulic test bench (maximum force 2500kN) (see Photo 3)

- Vibrophore and rotating fatigue machine

- Ovens and thermal and induction heat test chambers

Evaluating the effect of microstructure on materials’ mechanical behavior

- Instrumented micro- and nano-hardness testing machines (formerly Anton Paar TriTec SA)

- METRAVIB DMTA machine with IR measurement

- Differential scanning calorimeter (DSC)

- Electrodynamic testing machine (±3.2kN, ±24N.m)

- Netzsch 402P differential dilatometer

- Shimadzu TGA-50H thermogravimetric analyzer

- Cryogenic chamber

Cutting-edge equipment for measurement and analysis

Motional and temperature field measurement equipment:

- 2 infra-red FLIR SC7000 cameras (see Photo 6)

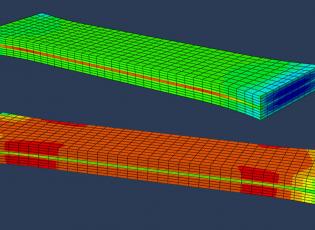

- 2 GOM ARAMIS stereo digital image correlation systems (see Photo 7)

- FASTCAM high-speed camera and 3 CCD cameras

- X-ray diffractometer (DRX) and other equipment associated with this observation method, including a dosimeter

Analysis and observation equipment:

- 2 optical microscopes (including one 3D digital microscope), scanning electron microscope, etc.

- 1 scanning electron microscope and associated equipment, including Discotom, back-scattered and secondary electron detectors, EDS and EBSD analysis systems, and on-site tension-compression test bench

- High-frequency signal acquisition equipment

Production of samples and parts for experimental set-ups

- SABRE 1000 vertical machining center,

- Alcera Gambin milling machine

- Colchester CNC lathe

- Weiler Primlus CNC lathe and Gallic 16N conventional lathe

contact